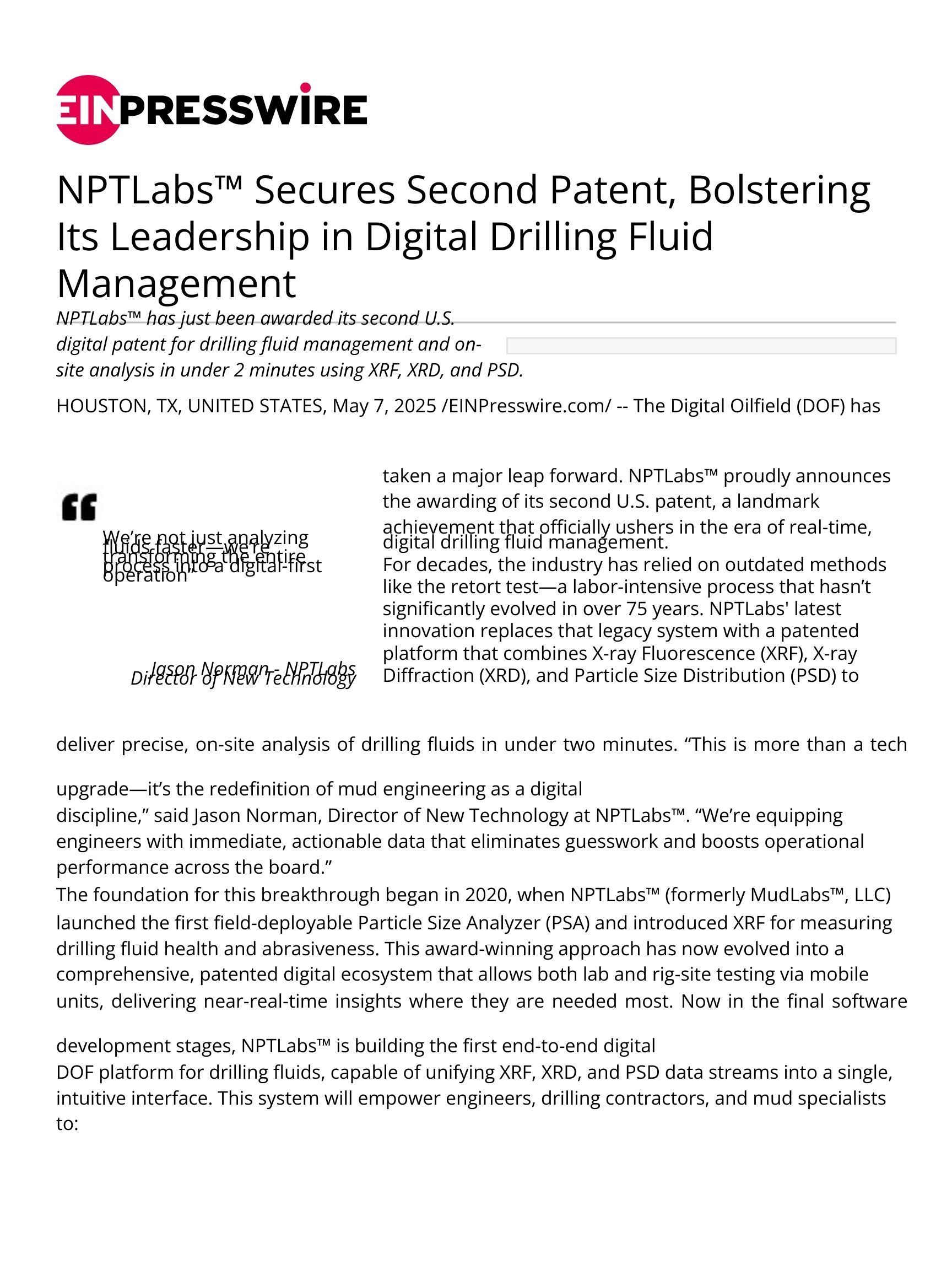

NEW GRANTED PATENT

Drilling Fluid Adjustment Using Real-Time XRF, XRD, PSA, and Mud Checks

Methods and Systems for Adjusting Drilling Fluid

Core Summary:

This utility patent describes an integrated, real-time or near-time system for measuring, analyzing, and adjusting drilling fluids by combining four key analytical techniques:

- X-ray Fluorescence (XRF) – Determines elemental composition of solids in the mud.

- X-ray Diffraction (XRD) – Identifies crystalline minerals (e.g., quartz) and quantifies formation materials.

- Particle Size Analysis (PSA) – Tracks size distribution of solids to ensure optimal fluid rheology and abrasiveness control.

- Mud Checks – Provides traditional physical-chemical fluid properties (e.g., density, viscosity, solids).

These analyses are continuously used to detect abrasive low-gravity solids (LGS)—especially quartz/sand—and to recommend or automatically execute corrective actions using solids control equipment (e.g., centrifuge g-force adjustments, dilution, retention time changes). This enables real-time adjustment of mud properties and solids content before re-circulation.

Value to the Digital Oilfield:

This patent is highly valuable to the modern digital oilfield because it:

- Creates a closed-loop, AI-ready system:

- Enables automation of drilling fluid conditioning using real-time data.

- Integrates seamlessly into digital twin and rig automation systems.

- Reduces Invisible Lost Time (ILT) and Non-Productive Time (NPT):

- Identifies abrasive solids before they damage downhole tools.

- Prevents tool failures, stuck pipe, and premature bit wear.

- Optimizes solids control:

- Moves beyond simple volumetric cuttings removal to mineral-specific decontamination, prioritizing wear-reducing actions.

- Improves ESG performance:

- Reduces contaminated waste volumes and fluid disposal requirements.

- Enhances drilling efficiency, lowering energy use and carbon intensity.

- Enables Predictive Maintenance:

- Links particle mineralogy and size with equipment wear trends, feeding into predictive analytics for rig components.

- Supports advanced analytics platforms:

- Can be embedded in cloud-based dashboards and edge-processing systems.

- Provides structured, high-frequency data streams suitable for AI/ML optimization.

What Makes This Patent So Valuable:

- First-of-its-kind combination of XRF, XRD, PSA, and Mud Check in a real-time decision system.

- Shifts drilling fluid optimization from empirical to scientific and data-driven—linking mineralogy directly to tool wear risk.

- Enables the development of next-gen solids removal KPIs, such as wear potential per barrel, not just volume of solids removed.

- Lays the groundwork for fully autonomous fluids management systems in future unmanned or semi-manned rigs.

- Addresses a known gap in drilling best practices—the lack of mineral-specific abrasiveness tracking in real-time.

- Protects a closed-loop architecture that can be commercialized across hardware/software integrations (e.g., sensor OEMs, rig software providers, mud companies).

Final Takeaway:

This patent is a cornerstone IP for digitizing fluids management, protecting a smart, automated, and mineral-aware system that can revolutionize how the industry measures, manages, and maintains drilling fluids—leading to safer, faster, and more cost-effective wells in any environment.

PATENTS USA | CANADA | EU

US Patent

Canada Patent

European Patent

A patented method for optimizing drilling fluids by creating a proper particle size analysis and distribution curve of particle sizing within drilling fluid. The particle size distribution curve is maintained with a maximum particle sizing of 6 microns to not allow for coarser drilling solids to degrade beyond the point of mechanical separation to prevent a build-up of low gravity solids that can no longer be removed from drilling fluid during the drilling operation due to their size.

An optimal drilling system requires that drilling fluids be modified through the following process to attain the appropriate particle sizing distribution to make the most efficient use of the drilling operation, prevent downhole tool failures and reduce the number of drilling fluids utilized, and reduce formation damage.

The method generates corrective actions to modify the drilling fluids or adjust solids control equipment parameters, to obtain an optimal particle size distribution throughout the drilling process.

In the process of integrating Artificial Intelligence into our Patented process for PSA (Particle Size Analysis), Patent Pending technology for XRF (X-Ray Fluorescence) and XRD (X-Ray Diffraction) to further enhance our drilling optimization capabilities.

Graphic Analysis